YOU MAY ALSO BE INTERESTED IN

Self-supported coils: Facts about coils made of selfbonding wire

Self-supported coils are coils made of wire that is coated with a thermoplastic layer - the bonding varnish. The term selfbonding enamel wire already indicates it: This wire is bonded during the winding process to give the coil the necessary stability without any other aids, especially in the case of air coils. The use of selfbonding wire can offer advantages over a bobbin coil in some cases, ...

How to select a strategic coil manufacturer for automotive Tier 1 or 2 suppliers

The automotive industry is undergoing a profound transformation driven by the rise of e-mobility and evolving customer expectations for comfort and entertainment. As automakers strive to deliver innovative and high-performance vehicles, contract manufacturers play a pivotal role in supporting their supply chains.

Insulation layer on magnet wires: A common stumbling block for engineers

In coil production, the insulation of the wire has an influence on a wide variety of product properties such as application range, service life, costs or coil design. Wire insulation also has an effect on various factors during coil manufacturing, such as scrap or further processing. This article summarises the essential facts about wire insulation - and its effect on coil design - for engineers.

These are the areas in which micro coils are generating major innovations

Coil manufacturing in the medical field has revolutionized the way we approach healthcare. The micro coils or sensors required for many medical technology applications are becoming increasingly powerful, while at the same time requiring less space. The applications of miniature coils in the medical field are vast, ranging from diagnostic and therapeutic uses to navigation and orientation ...

Why Lean methods are beneficial in coil and electronics production

Anyone who knows Lean as a production method is probably familiar with the benefits of Lean. But what is Lean actually? How can you use Lean to speed up business processes? Learn more about Lean management methods that KUK Group, as a leading manufacturer of coils and electronics, applies itself.

What is important when choosing an electric coil manufacturer?

Selecting the right coil manufacturer is a crucial factor for the success of your project. A professional coil manufacturer should have the necessary experience and expertise to meet your specific requirements. Additionally, you should look for technological advancements and flexibility in production. A good coil manufacturer adapts to changes and ensures that the coils meet high-quality ...

No series production without tools

In today's tumultuous supply chain landscape, companies are struggling to maintain their footing. Yet, the ability to quickly establish a series production for customised coil manufacturing can be a game-changer. Of course, the key to successful series production lies in having the right tools. At KUK Group, we understand this better than anyone, which is why we predominantly manufacture our ...

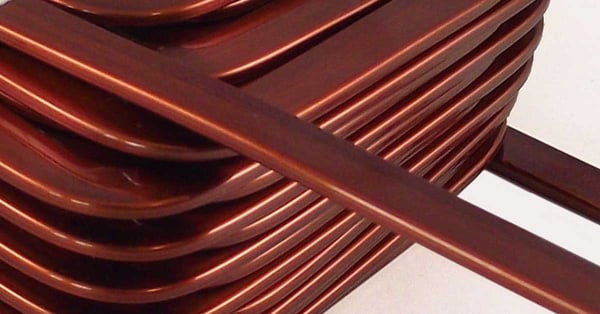

What material can coils be wound from?

In coil production, the wire used plays a central role. While copper is undoubtedly the most commonly used conductor material, especially for customer-specific coil projects, it is also worthwhile to test alternative coil wire, depending on the application.

What makes a successful development project for coils production?

Engineers are aware of the challenges that await them in the feasibility phase. Especially with customised inductive components, it often takes several attempts until the optimal solution is found. This is a case for the development team of the KUK Group, the leading manufacturer of customised coils and electronics.

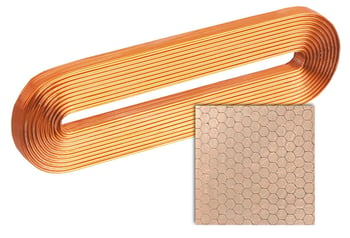

What is the advantage of orthocyclic windings?

Orthocyclic coils are characterised by a high copper fill factor (often approx. 70%), so that a comparatively high magnetic field is realised in the smallest possible space.

READY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.