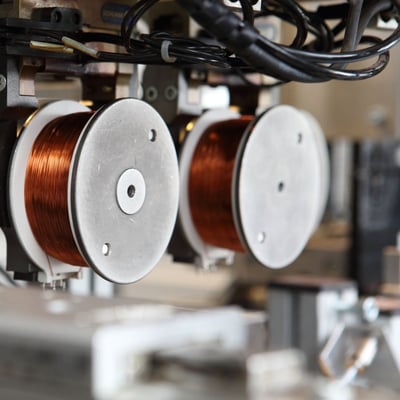

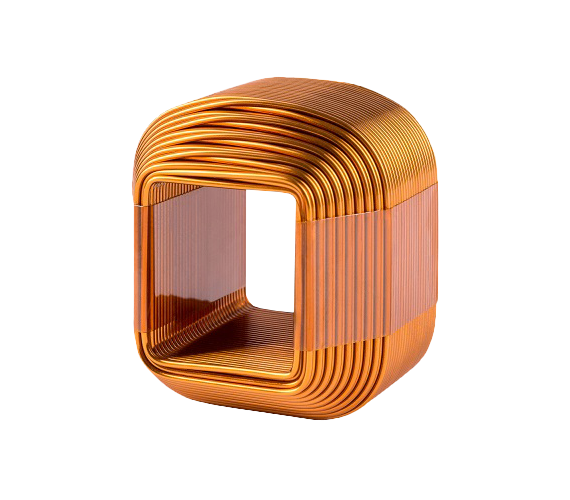

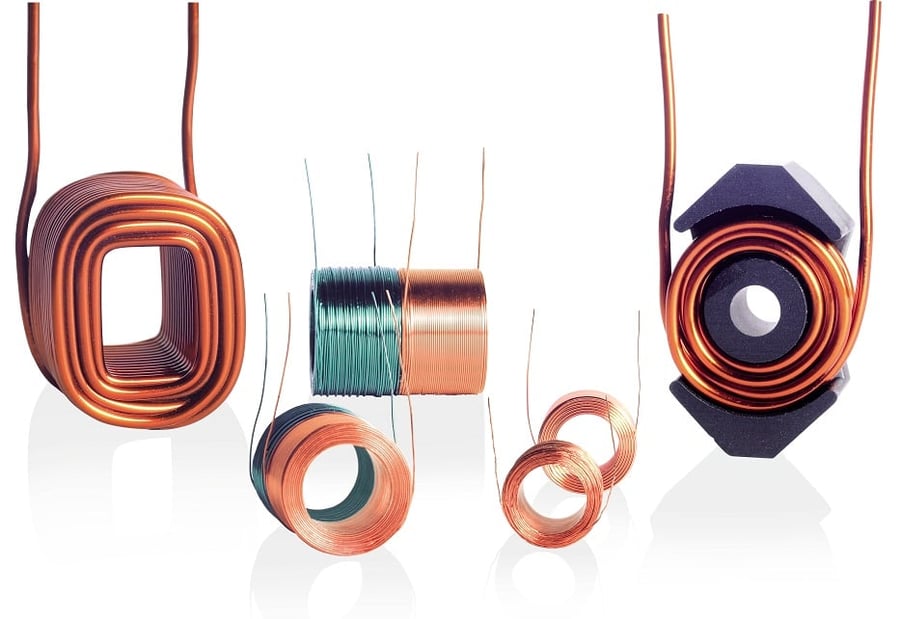

Air core coil odd-shaped

TAILOR-MADE AIR COILS IN ALL SHAPES

KUK manufactures your air coil according to your specific requirements: all geometries, wire forms as well as orthocyclic windings are possible. We also have extensive experience in the production of self-bonding or self-supporting coils.

OVERVIEW AIR COIL ODD-SHAPED

- Layer winding

- High-temperature-stable winding

- Tin-plated leads

- Leads with strands, connectors

- Varnished copper wires

- Selfbonding wires

- High temperature

- Aluminum wires (copper-plated)

- Litze wires

- Formed coils

- Stepped windings

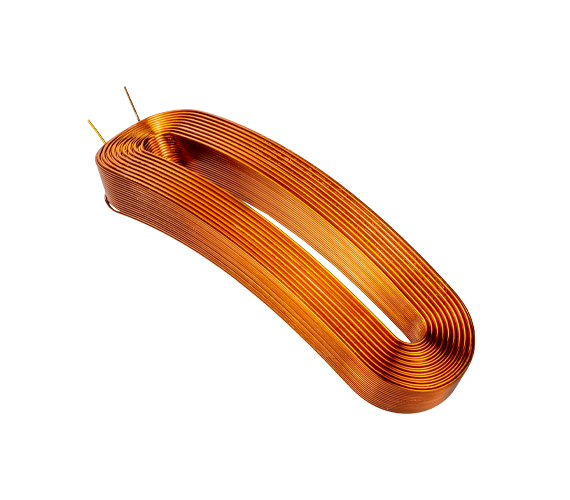

- Specialty: Patent coil with start and end wire located on the outer diameter of the coil

Customer-specific solutions are our speciality

Andreas Wild and the product team will be happy to advise you.

ADVANTAGE OF ORTHOCYCLIC WOUND COILS

Orthocyclic windings allow the ‘densest possible stacking’ of turns. A transverse section of an orthocyclic coil would have a honeycomb shape. Orthocyclic coils are characterised by a high copper fill factor (often approx. 70%), so that a comparatively high magnetic field is realised in the smallest possible space.

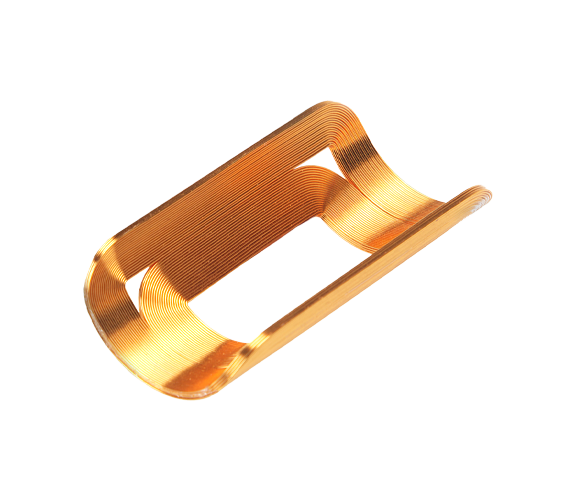

EDGEWISE WINDING IN A NUTSHELL

Edgewise winding is one of the modern trends in coil manufacturing. The principle of this winding technology is that the rectangular section wire is wound not on the short side, but on the flat part of the wire. That’s what the terms edgewise winding or side-winding stands for.

OUR KNOW-HOW AND SERVICES

.png?upsize=true&upscale=true&width=72&height=72&name=settings(1).png)

.png?upsize=true&upscale=true&width=512&height=512&name=delivery(1).png)

Process partner from product idea to large-scale production

KUK serves the customer according to individual requirements from development phase to the integration of the goods into the global supply chain.

More

Based on our innovative winding technology, we wind our KUK patent air coils on a fully automatic winding machine. The start and end wire of the coil are located on the outer diameter of the coil, which saves space. In addition, the coil can be embedded flattened into a ferrite without resting on the starting wire.

READY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.